Looking for a reliable dolomite limestone crusher can be essential in industries like mining, construction, and agriculture. Dolomite, a mineral with a high magnesium content, and limestone, a calcium-rich stone, are often processed together for various applications. The right crusher can make a significant difference, ensuring efficient and precise crushing of these materials. Many types of crushers, including jaw crushers, cone crushers, and impact crushers, are suitable for dolomite limestone applications, with each type offering unique advantages depending on specific processing needs.

For primary crushing, a jaw crusher is often the preferred choice due to its durability and high crushing ratio. Jaw crushers are built to handle large, rough rocks, making them perfect for processing hard minerals like dolomite and limestone. They break down large stones into smaller sizes suitable for secondary processing, providing a reliable foundation for the entire crushing operation. Additionally, jaw crushers are versatile and come in various models, allowing buyers to choose the size and power that best suit their project requirements.

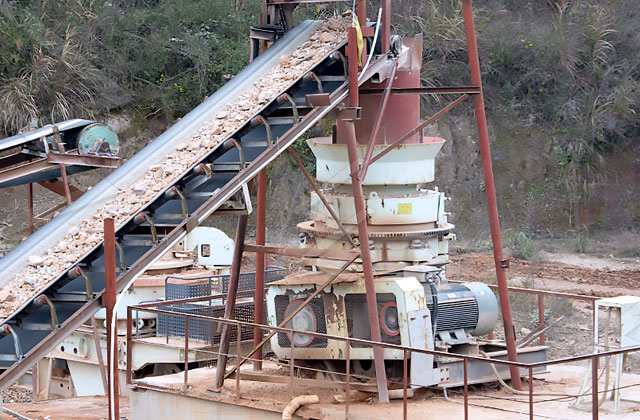

Secondary and tertiary crushing stages often involve cone crushers, which are ideal for dolomite limestone as they provide finer and more consistent output. Cone crushers apply compressive force to break down materials, resulting in uniform particle sizes and efficient use of energy. This crushing method is advantageous for dolomite limestone because it minimizes waste and produces a well-rounded end product. Advanced models of cone crushers also feature automation systems, enhancing efficiency by monitoring parameters like pressure and material feed.

Impact crushers are another effective option for dolomite limestone processing, particularly for creating high-quality aggregate. Known for their high reduction ratios, impact crushers work by propelling material against a series of hammers or blow bars. This setup makes them suitable for materials like dolomite limestone, where crushing for shape and size consistency is crucial. Impact crushers are versatile in their output, making them highly desirable in the construction industry where specific sizes and shapes are often needed.

In summary, the right dolomite limestone crusher can optimize production efficiency, reduce operational costs, and enhance material quality. With options like jaw crushers for primary crushing, cone crushers for secondary and tertiary stages, and impact crushers for specialized aggregate production, buyers have many choices to meet their unique requirements. Whether for large-scale mining operations or smaller construction projects, a suitable crusher can ensure a successful outcome for any dolomite limestone processing line.