Overview of Potash Feldspar Sand Cone Crushers

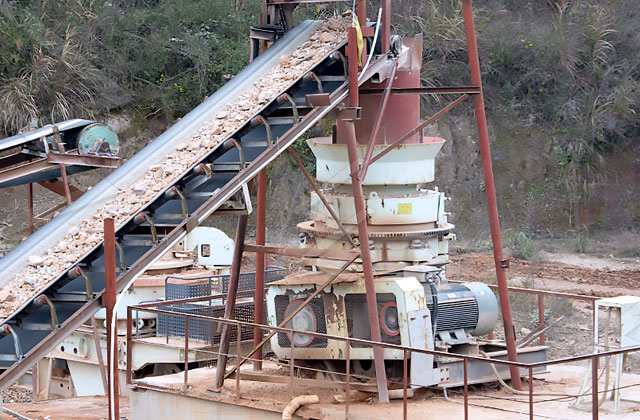

Potash feldspar, a significant mineral in the production of glass and ceramics, is often processed using specialized equipment to meet industry standards. One effective solution for this processing is the sand cone crusher, which plays a vital role in crushing and shaping potash feldspar into usable sand. This equipment not only enhances the efficiency of mineral extraction but also improves the quality of the final product.

Importance of Cone Crushers in Processing Potash Feldspar

Cone crushers play a crucial role in the processing of potash feldspar, offering advantages such as high reduction ratios and improved product shape. These machines are particularly effective in reducing the size of large potash feldspar rocks into smaller, more manageable particles. The ability to handle tough materials while providing consistent performance makes cone crushers an ideal choice for mineral processing operations. They not only enhance productivity but also minimize wear and tear, ensuring lower operational costs over time.

Key Features of Potash Feldspar Cone Crushers

Modern cone crushers designed for potash feldspar processing come equipped with several key features. These include advanced hydraulic systems for easy adjustments, a robust construction for longevity, and customizable settings to meet specific material requirements. Many models also feature automated controls that optimize crushing parameters, ensuring a uniform product size and reducing the risk of oversize or undersize materials. Additionally, their versatility allows them to handle various types of feed material, making them a valuable asset in a mining operation.

Economic Benefits of Using Cone Crushers

The economic benefits of using cone crushers for potash feldspar processing are significant. By efficiently reducing material size and improving product quality, these crushers contribute to increased yield and reduced waste in production. The lower operational costs, combined with high throughput rates, allow companies to maximize their profit margins. Furthermore, the durability and reliability of cone crushers minimize downtime, ensuring that production remains consistent and profitable.

Conclusion

In conclusion, the use of cone crushers in the processing of potash feldspar is essential for meeting the growing demands of the ceramics and glass industries. Their ability to efficiently crush tough materials while maintaining product quality makes them indispensable in mineral processing operations. As technology continues to advance, these machines will likely evolve, offering even greater efficiency and productivity, ultimately enhancing the economic viability of potash feldspar extraction and processing.