Vibrating Screens: An Overview

Vibrating screens are essential components in many industries, including mining, construction, and recycling, where they are used to separate materials into different size fractions. Their main function is to sort and grade materials efficiently, ensuring the desired output quality and meeting specific standards.

Principle of Operation

The basic principle of a vibrating screen involves the use of vibration to induce movement in the screen surface. This movement causes the particles to stratify according to size and density, allowing smaller particles to pass through mesh openings while larger particles are retained.

- Vibration Mechanism: The screen is typically mounted on springs and equipped with a vibratory motor or a set of counterweights that create the necessary motion. This motion can be linear, circular, or elliptical, depending on the design and application of the screen. The vibration ensures that the particles move across the screen surface and are sorted efficiently.

- Screen Surface: The screen surface, often made of wire mesh or perforated plate, is designed to withstand the wear and tear of continuous use. The mesh size is chosen based on the desired separation and the nature of the materials being processed. Multiple layers of screens may be used to achieve different size classifications.

Components of Vibrating Screens

A vibrating screen typically consists of several key components:

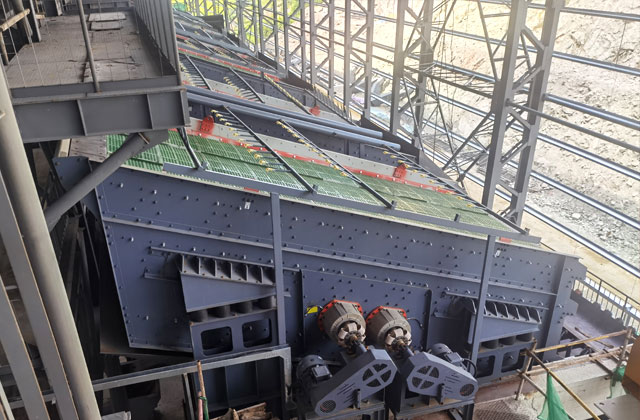

- Screen Deck: This is the surface through which material is screened. It is usually made of mesh or perforated metal and can be made from various materials depending on the application and the size of the particles being screened.

- Vibration Mechanism: This is the system that generates the vibrating motion. It can include eccentric weights, springs, or vibratory motors. The choice of mechanism affects the efficiency and effectiveness of the screen.

- Frame: The frame supports the screen deck and vibration mechanism. It is usually constructed from heavy-duty materials to withstand the stress and strain of the screening process.

- Support Springs: These springs absorb the vibrations generated by the mechanism and help to maintain the stability of the screen.

Advantages

Vibrating screens offer several advantages:

- Efficiency: They provide effective separation and classification of materials, improving the quality of the output.

- Versatility: They can handle a variety of materials and can be adjusted to accommodate different sizes and types of material.

- Durability: Designed to withstand harsh conditions, they have a long operational life with minimal maintenance.

Maintenance and Troubleshooting

Proper maintenance is essential for the longevity and performance of vibrating screens. Regular inspection of the screen mesh, vibration mechanism, and structural components is necessary to prevent issues such as clogging, excessive wear, and vibration problems. Common troubleshooting involves checking for proper alignment, adjusting the vibration amplitude, and ensuring that the screen is clean and free of debris.