Introduction to Bauxite Screening Equipment

Bauxite, an essential raw material in the aluminum production process, requires efficient screening to ensure the separation of fine particles from larger ones. This screening process is critical in enhancing the quality and efficiency of bauxite processing. The equipment used for screening bauxite varies in design and function, including vibrating screens, trommel screens, and other specialized machinery tailored to meet specific processing needs. This article explores the various types of bauxite screening equipment available for sale, their features, and the benefits they offer to operators in the mining and processing industries.

Types of Bauxite Screening Equipment

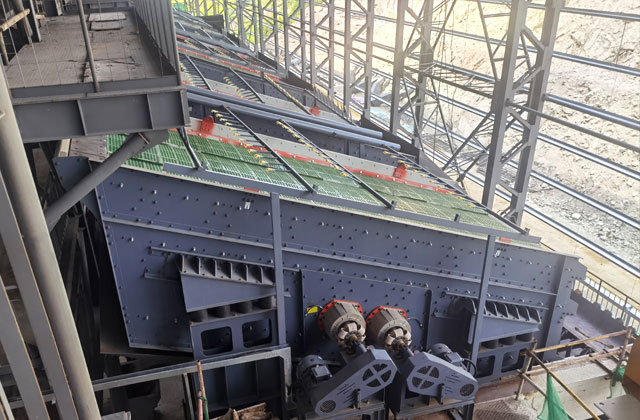

Several types of screening equipment are designed specifically for bauxite processing. Vibrating screens are among the most common, utilizing high-frequency vibrations to separate materials based on size. These screens can efficiently handle large volumes of material while providing precise separation of different particle sizes. Trommel screens, on the other hand, feature a rotating cylindrical design that allows bauxite to be screened as it moves through the cylinder. This method is particularly effective for removing larger debris and oversize particles from the bauxite mix, ensuring a cleaner end product.

Features of Bauxite Screening Equipment

When selecting bauxite screening equipment, several features should be considered to optimize performance. Key aspects include screen size, mesh openings, and the material construction of the equipment. High-quality materials like stainless steel or carbon steel are preferred for durability and longevity. Additionally, adjustable screen angles and variable vibration frequencies can enhance the efficiency of the screening process, allowing operators to customize the equipment according to their specific bauxite processing needs. Features such as ease of maintenance and portability can also influence the choice of screening equipment.

Benefits of Investing in Quality Screening Equipment

Investing in quality bauxite screening equipment offers numerous benefits, including improved product quality, increased operational efficiency, and reduced operational costs. Efficient screening ensures that the bauxite is processed to meet the specific requirements of aluminum production, which can lead to higher yields and better-quality aluminum products. Additionally, modern screening equipment is often designed to consume less energy and require less maintenance, reducing overall operational costs. This efficiency translates into higher profitability for mining operations.

Conclusion and Purchasing Considerations

As the demand for aluminum continues to grow, so does the need for effective bauxite screening equipment. When considering the purchase of screening machinery, it’s crucial to evaluate the specific requirements of your operation, including the volume of bauxite to be processed, the desired separation efficiency, and the available budget. Engaging with reputable suppliers and manufacturers can provide valuable insights and help ensure the selection of the most appropriate screening equipment for your bauxite processing needs. With the right machinery, operators can enhance their productivity and contribute to the overall success of their mining operations.