Stone crushers play a vital role in mining, quarrying, and construction industries by reducing large rocks into smaller aggregates or gravel. Installing a stone crusher properly is crucial to ensure safety, efficiency, and longevity of the equipment. This article provides a step-by-step guide for stone crusher installation, including planning, site preparation, equipment setup, and commissioning.

1. Introduction to Stone Crusher Installation

Stone crusher installation involves setting up the crushing equipment and auxiliary machinery on a designated site so that it functions optimally. Proper installation maximizes output capacity, reduces downtime, and enhances safety for operators.

2. Types of Stone Crushers

Before installation, it’s important to know the type of crusher involved, as installation requirements differ:

-

Jaw Crusher: For primary crushing; uses compressive force.

-

Impact Crusher: Uses impact energy for secondary crushing.

-

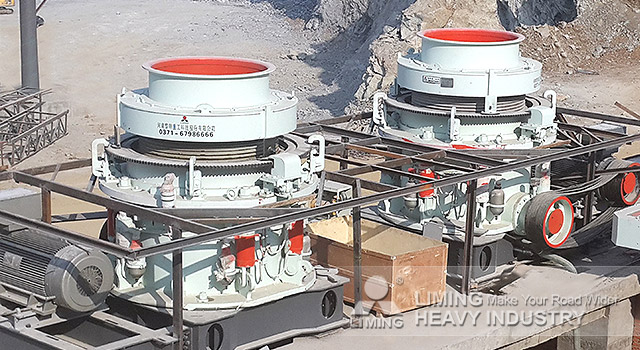

Cone Crusher: For secondary or tertiary crushing; uses compressive force.

-

Hammer Crusher: Uses high-speed rotating hammers for crushing.

-

Roll Crusher: Uses compression between two rollers.

3. Pre-Installation Planning

3.1 Site Selection

-

Choose a flat, stable site with good drainage.

-

Ensure accessibility for raw materials and transportation.

-

Check for space for auxiliary equipment and future expansion.

3.2 Foundation Design

-

Prepare a concrete foundation capable of supporting the crusher weight and vibrations.

-

Consider soil bearing capacity; reinforce with steel bars if necessary.

-

Plan for drainage channels to avoid water accumulation.

3.3 Equipment Inspection

-

Inspect all crusher parts for damage during transportation.

-

Verify all components and accessories are available.

-

Read manufacturer’s manual for installation specifics.

4. Installation Procedure

4.1 Foundation and Mounting

-

Level and clean the foundation area.

-

Place anchor bolts as per the layout drawings.

-

Mount the crusher frame securely on the foundation.

-

Use leveling tools to ensure the crusher is perfectly aligned.

4.2 Assembly of Crusher Components

-

Install the crusher body, jaw plates, or impact hammers according to type.

-

Attach auxiliary components like motors, pulleys, belts, and flywheels.

-

Ensure proper alignment of shafts and bearings.

-

Lubricate moving parts before starting.

4.3 Electrical and Control Setup

-

Install the motor and connect electrical wiring as per standards.

-

Set up control panels for start/stop, emergency stop, and safety interlocks.

-

Check electrical connections with a qualified electrician.

4.4 Installation of Feed and Discharge Systems

-

Install the hopper, feed conveyor belt, and chute for smooth material feeding.

-

Set up the discharge conveyor belt or storage bins for crushed material.

-

Align conveyors to avoid spillage and jams.

5. Testing and Commissioning

5.1 Dry Run

-

Run the crusher without load to check mechanical functioning.

-

Verify rotation direction and smooth operation.

-

Listen for unusual noises or vibrations.

5.2 Trial Run with Material

-

Gradually introduce material feed.

-

Monitor crushing efficiency, output size, and capacity.

-

Adjust settings such as jaw gap, impact plate distance, or crusher speed if necessary.

5.3 Safety Checks

-

Confirm all safety guards and covers are in place.

-

Train operators on emergency procedures.

-

Regularly inspect lubrication points.

6. Maintenance and Troubleshooting Tips

-

Establish a regular lubrication schedule.

-

Replace worn-out jaw plates or hammers timely.

-

Monitor bearing temperatures and vibration levels.

-

Keep the crusher clean to avoid clogging.

Proper installation of a stone crusher is key to its performance and lifespan. It requires thorough planning, precision in assembly, electrical safety, and careful commissioning. Following the steps outlined ensures efficient crushing operations, safe working conditions, and long-term equipment reliability.

If you need assistance with a specific type of crusher installation or want detailed engineering drawings, I can help with that too. Would you like me to focus on a particular crusher type or installation scenario?