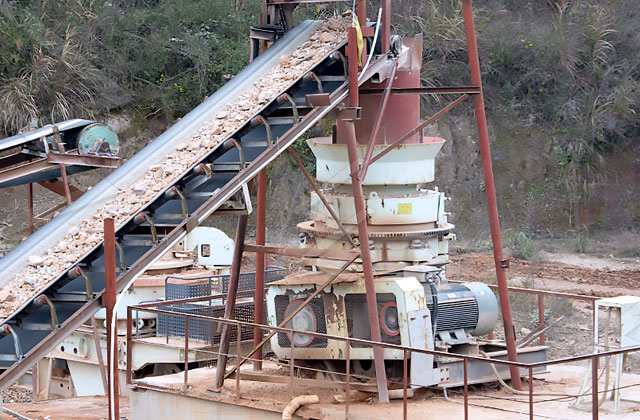

A 150 TPH (Tons Per Hour) Granite Cone Crusher is a powerful machine specifically designed for high-efficiency crushing of granite, one of the hardest and most commonly found natural stones. Granite is widely used in construction, and having a reliable and efficient crusher is essential for mining operations, particularly for producing aggregate material for road building, construction, and other industrial purposes.

Key Features and Benefits of a 150 TPH Granite Cone Crusher:

- High Crushing Capacity: A 150 TPH granite cone crusher is designed to process 150 tons of granite material per hour. This makes it an excellent choice for medium-scale production lines that need a steady throughput of high-quality crushed material. The efficiency of the cone crusher ensures maximum output while minimizing energy consumption, making it a cost-effective option for high-volume operations.

- Optimal Crushing Performance: Cone crushers are known for their ability to crush hard and abrasive materials like granite. They use a rotating mantle and a concave to compress the material between them, ensuring that the granite is broken down into smaller, more manageable sizes. The shape and size of the output can be controlled by adjusting the gap between the mantle and concave, which allows operators to produce a range of crushed products, from fine aggregates to larger stones.

- Durable Construction: Granite is a tough material, and crushers designed to handle it must be built to last. A 150 TPH granite cone crusher is constructed with heavy-duty materials, including high-strength steel and advanced wear-resistant components. The robust design ensures durability and longevity, even under the constant stress of crushing hard rocks. The cone crusher also has built-in safety features to protect the machine from overloads and other operational hazards.

- Versatile Applications: A 150 TPH granite cone crusher can be used in various industries, including construction, road building, mining, and aggregate production. The crushed granite can be used in a variety of applications, such as for concrete production, road base material, and landscaping projects. The versatility of the cone crusher makes it suitable for multiple crushing stages in a complete aggregate production line, from primary to secondary and tertiary crushing.

- Advanced Control Systems: Many modern cone crushers come equipped with advanced control systems that allow operators to monitor and adjust various parameters such as feed rate, output size, and operating temperature. These systems improve the efficiency and performance of the crusher, allowing for optimal production levels and reduced wear on parts. Remote monitoring systems may also be available, enabling operators to manage the crusher from a central location.

A 150 TPH granite cone crusher is a cost-effective solution for medium-scale granite processing projects. Its high capacity, performance optimization, energy efficiency, and low maintenance make it a reliable choice for companies in the construction and aggregate industries. With proper installation, maintenance, and operation, it can deliver consistent results and maximize profitability for the user.