If you’re in the market for a granite mining stone crusher, it’s essential to understand the requirements and the range of crushers available for sale to meet the needs of your operation. Granite is a dense and tough material, making it a popular choice in construction projects. However, extracting and processing granite requires specialized equipment, and a suitable stone crusher is essential to break the rock into smaller, usable pieces.

Types of Granite Stone Crushers

Granite crushers are typically categorized based on their crushing mechanism and size reduction capacity. The most common types include:

- Jaw Crushers: These crushers are primarily used for the initial stage of granite mining. Jaw crushers are designed to handle large chunks of rock and break them into manageable sizes. They are suitable for reducing large granite boulders to smaller pieces, ideal for secondary processing.

- Cone Crushers: Cone crushers are used for secondary and tertiary crushing. Once the granite has been reduced by a jaw crusher, a cone crusher can further reduce it to finer sizes, making it suitable for applications like making aggregates or sand. They offer high reduction ratios and are ideal for hard materials like granite.

- Impact Crushers: These crushers use high-speed impact to break the rock into smaller particles. They are typically used for softer or medium-hard stones but can be equipped with special features to process granite. They work well for producing finer aggregates, especially for asphalt and concrete production.

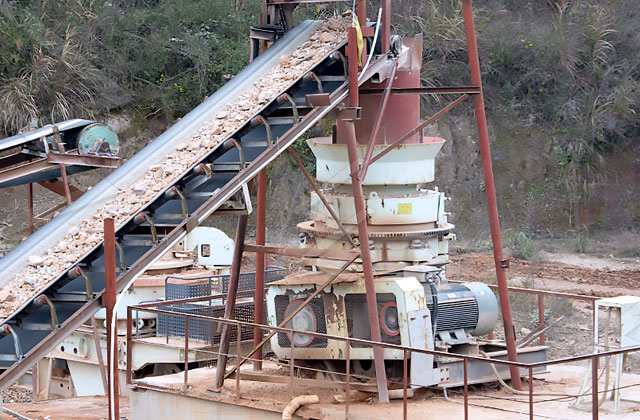

- Vertical Shaft Impact (VSI) Crushers: These crushers are used to produce high-quality manufactured sand and are capable of making uniform, cubical products. VSI crushers are ideal for making fine aggregates from granite rock, and they can handle a variety of materials besides granite.

Features to Consider When Purchasing a Granite Crusher

When choosing a granite stone crusher, several factors need to be considered to ensure the equipment meets your needs:

- Capacity: Granite crushers come in various sizes with different throughput capacities. It’s essential to select a crusher with the appropriate capacity to handle your required volume of granite efficiently. Crushers are rated by their capacity, usually in tons per hour (TPH), with options ranging from small-scale machines to large industrial crushers.

- Durability and Material Quality: Granite is a tough material that can wear down crushers over time. Look for crushers made with high-quality materials, such as manganese steel, which is highly resistant to wear. This ensures longer-lasting performance and reduced maintenance costs.

- Customization: Depending on your specific requirements, some manufacturers offer crushers with customization options, including different types of wear-resistant linings or adjustable discharge settings to optimize performance for granite.

Advantages of Granite Crushers for Sale

Buying a granite mining stone crusher can be a significant investment, but it offers several advantages:

- Cost-Effectiveness: Owning a crusher means you’re not dependent on third-party crushing services, which can add up in the long term.

- Customization and Control: You have the flexibility to choose equipment that aligns with your specific mining process and stone sizes.

- Improved Efficiency: Modern crushers are designed to work faster and more efficiently, reducing the time spent processing granite and maximizing output.

Whether you’re starting a granite mining operation or upgrading existing equipment, choosing the right stone crusher is crucial for maximizing efficiency and ensuring long-term success. Various types of crushers, such as jaw, cone, impact, and VSI crushers, offer different advantages depending on your needs. When buying a granite crusher, it’s essential to consider capacity, material quality, energy efficiency, and customization to ensure that your equipment can handle the challenging nature of granite mining.