When it comes to dolomite gravel crushing, the choice of equipment plays a critical role in ensuring effective processing. Dolomite is a sedimentary carbonate rock, primarily composed of calcium magnesium carbonate, making it an important material in construction, road building, and industrial processes. Crushing dolomite gravel requires specialized machinery to achieve the right size and shape for specific applications, ranging from aggregates in concrete to filler material for asphalt production.

1. Jaw Crushers for Primary Crushing

Jaw crushers are frequently used as the primary crusher in dolomite gravel production lines. These machines are capable of handling large rocks and breaking them into smaller, manageable pieces. The robust design of jaw crushers ensures that they can withstand the heavy-duty crushing of dolomite rocks, which tend to be relatively hard. The adjustable setting of the crusher allows for control over the size of the output, making them ideal for producing dolomite gravel in various sizes.

2. Impact Crushers for Secondary Crushing

Impact crushers are often used for secondary crushing of dolomite. These crushers use impact force to break down materials and can produce well-shaped, fine dolomite gravel. The adjustable speed and rotor of impact crushers allow operators to customize the fineness of the output to meet specific needs. This makes them a popular choice for industries requiring specific particle sizes, such as road construction and concrete production.

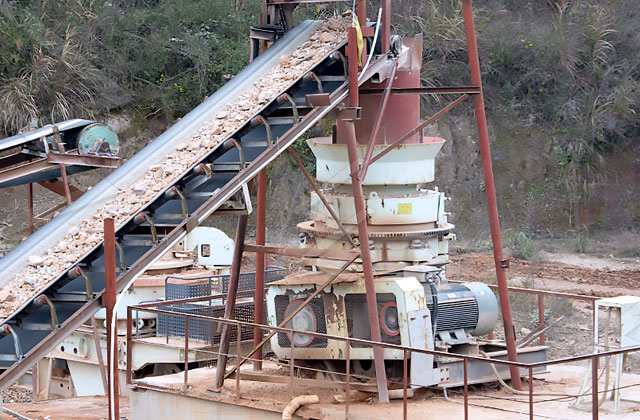

3. Cone Crushers for Fine Crushing

When fine or ultrafine dolomite gravel is required, cone crushers are the go-to equipment. These crushers apply a compressive force to crush the material, ensuring the production of uniform, high-quality gravel. The design of cone crushers allows for the crushing of harder dolomite rock into fine gravel, making it suitable for specialized applications such as landscaping or drainage systems. They are also known for their energy efficiency, as they require less power compared to other crushing equipment.

4. Portable Crushing Equipment for Mobility

Portable crushers provide an ideal solution for dolomite gravel processing in remote areas or construction sites with limited space. These mobile crushers can be easily transported and set up, providing flexibility in crushing operations. Whether it’s a portable jaw crusher or a portable cone crusher, this type of equipment allows for on-site processing, reducing transportation costs and enabling continuous operations, even in hard-to-reach locations.

5. Vibrating Screens and Conveyors for Separation

After crushing, the dolomite gravel must be separated into different sizes for various applications. Vibrating screens and conveyors are typically used in this stage of production. Screens ensure that gravel is sorted into appropriate size fractions, while conveyors move the material efficiently between different stages of the crushing process. Together, they play a vital role in ensuring the consistency and quality of dolomite gravel production.

In conclusion, choosing the right dolomite gravel crushing equipment depends on the scale of the operation, the desired product size, and the specific application. Jaw crushers, impact crushers, cone crushers, and portable crushing equipment all offer unique advantages, from high efficiency and fine control to portability and ease of use. Selecting the appropriate machinery ensures optimal performance, cost-efficiency, and quality in dolomite processing.