When looking to buy a cone crusher for rock mining, it’s important to consider the specific requirements of your operation, such as the type of material being processed, desired output size, and production capacity. Cone crushers are vital equipment for various mining processes, especially for crushing hard materials like granite, basalt, limestone, and other ores. Here’s a detailed guide to help you make an informed purchase.

1. Understanding Cone Crushers for Mining

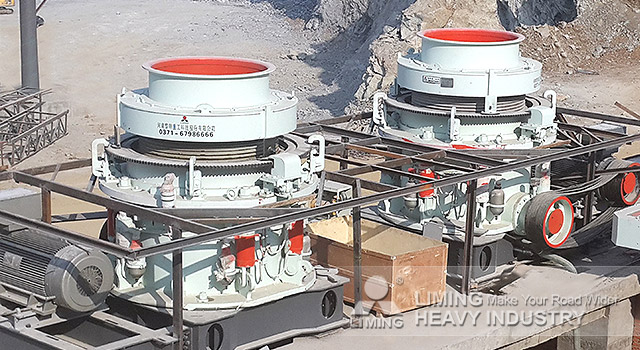

Cone crushers work by applying pressure to the material between a moving cone and a stationary cone. The material is crushed through compression, making them highly efficient for handling hard materials. In rock mining, cone crushers are ideal for secondary crushing stages. They are used to reduce the size of large rocks to smaller, more manageable pieces.

2. Capacity and Throughput

When buying a cone crusher, consider its capacity and throughput. This is directly related to the volume of material you need to process in your mining operation. Cone crushers come in various sizes and capacities, so it’s important to choose one that aligns with the amount of rock you plan to crush each hour. For example, if you require a large-scale crusher, a model with a higher throughput and larger crushing chamber might be ideal.

3. Crushing Chamber and Adjustment Mechanisms

The crushing chamber design plays a significant role in the efficiency and output of a cone crusher. Cone crushers offer a high degree of flexibility with their adjustable settings. You can control the size of the output material by adjusting the closed side setting (CSS), which directly influences the size of the crushed product.

Some cone crushers come with hydraulic systems that allow for easy adjustment of the crushing chamber and provide more control over the operation. This is especially useful when dealing with varying material types and sizes.

4. Durability and Maintenance

Durability is another critical factor when buying a cone crusher for mining. Crushers in mining environments are exposed to harsh conditions, so it’s important to select equipment built for heavy-duty operations. Look for crushers made from high-quality materials like manganese steel for wear-resistant components.

In terms of maintenance, cone crushers have a reputation for being relatively low-maintenance compared to other crushers. However, regular maintenance such as checking the lubrication system, inspecting wear parts, and replacing damaged components is essential to keep the crusher running efficiently.

5. Choosing the Right Supplier

When purchasing a cone crusher, ensure that you choose a reputable supplier with experience in the mining industry. A reliable supplier will provide comprehensive product support, including installation, maintenance, and troubleshooting. It’s also worth asking about warranties and service agreements to protect your investment.

Buying a cone crusher for rock mining requires careful consideration of the machine’s capacity, the material it will process, and the overall mining operation’s needs. With the right cone crusher, you can ensure efficient crushing, increased production, and reduced downtime in your mining operations. Don’t forget to consider the supplier’s reputation, after-sales support, and the crusher’s energy efficiency to maximize your investment in the long run.